How to repair P6 outdoor LED display sign board screen?

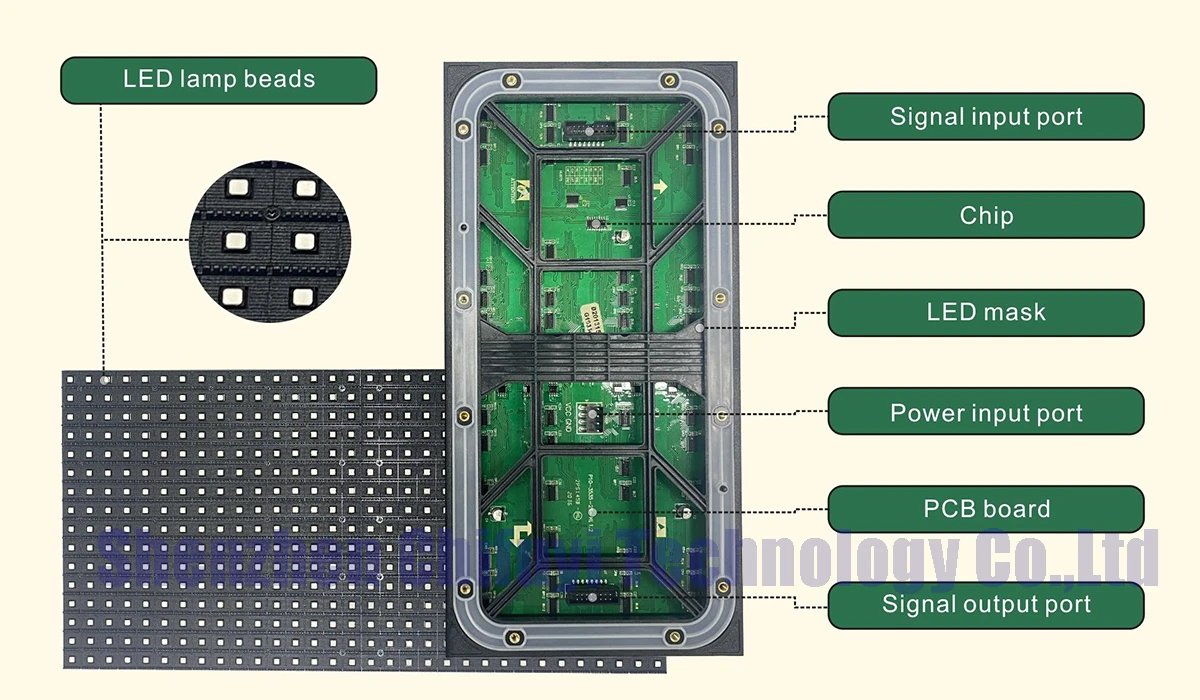

Have you ever encountered the P6 LED display suddenly showing black blocks, flickering, or color distortion? Don't panic! This is likely your LED module sending out an SOS. LED module failure is common as they are the core component of the LED display, but timely and professional repair can not only restore the perfect image but also save you the high cost of replacing the entire screen! Today, let's talk about the essentials of LED module repair………

Step 1 - LED Display Repair: Essential Tools Checklist

Before you begin repairing your LED display module, you need to gather the right equipment. Having the necessary LED repair tools ensures the maintenance process is efficient and successful.Here is a checklist of the tools you need to prepare:

Soldering Tools:Soldering Iron/Air Gun (Heat Gun)/Tin (Solder)/Copper Wire (Desoldering Braid/Wick)

Testing & Diagnostics:Multimeter/Receiving Card (for testing/configuration)/Power Supply/

Hand Tools:Tweezers/Screwdriver (Standard)/Mask Screwdriver (Specific tool for LED mask removal)

Cables & Accessories:Ribbon Cable/Power Cable/Black Glue (Sealant/Adhesive)

Components for Replacement:Module with Dead LEDs (The damaged module)/New LEDs (Replacement diodes)/New Module (If module replacement is needed)

Step 2 - Setting Up the Repair Environment

First, let's connect the LED modules and power up all the tools.I'll switch on the air gun and soldering iron. Once everything's powered up, let's confirm all these new friends are ready for action! (Wish me luck as I start this repair journey.)Next, I'll connect the power supply to our source—here it's 220V. A quick note: Power supplies vary globally (110V ~ 240V). Always double-check you’re using the correct voltage for your country.

Now, it’s time to breathe life into the screen. I'll power the receiving card and the LED module, and command the screen to display a series of pure colors: White, Red, Green, and Blue.

Ah! I see you, little faulty LED! Gotcha. Time to take you to the repair "hospital" for some urgent care.

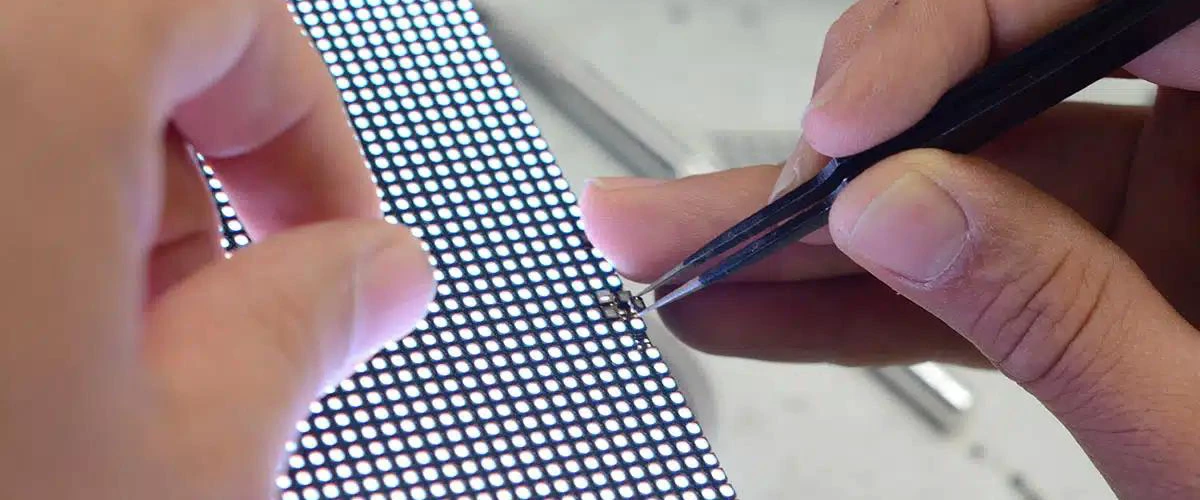

Step 3 - Safely Remove the Damaged LED LEDs

Step 4 - Assembling the New LED Pixel on the Module

Step 5 - Testing and Finalizing the Repair

Recommended:

3 simple steps! how to accurately calculate church LED display resolution

9 factors affecting the customization price of LED church displays